They are roughly the size and shape of an unshelled peanut and commonly made. Typically most secondary seals are flexible members that seal when they are deformed against the parts which have purpose designed cavities to accommodate these.

Ptfe V Packings Mechanical Shaft Seal O Rings

Blast chilling and vacuum packing.

. It has a full temperature rating of -7C to 316C 20F to 600F and still maintains the 100 ppmv leakage criteria. 112 Parker Court Chardon Ohio 44024. V150 V200 and V300 valves mate with a variety of.

These piston seals allow the cylinder to retract under pressure. Another design used on some single-acting telescopic cylinders is the use of soft zero leakage seals on the piston which in turn use the full bore of the next larger stage as. Standard mechanical seals can suit most requirements to temperatures of 500 degrees F and shaft speeds to 3600 RPM.

Marlin Standard with 2 seal bars. For example the side frames are made entirely of recycled ocean plastic. Packaging is the science art and technology of enclosing or protecting products for distribution storage sale and use.

Oil Seal Cross Reference Chart and Guide GBSA Oil Seals deliver top performance and outstanding wear. At the packing section of the main and moving stages. Theyre known around the world for their ability to prevent liquids and lubricants from leaking around rotary shafts and bearing housings.

Figs 520d 5. The design of this frameless machine also takes into account the CO2 footprint and the environment. Such as a sealing system for PE film MAP packing easy opening with pouring opening block bottom mechanism photocell for.

Packaging also refers to the process of designing evaluating and producing packages. Due to rubber piston seal and tight fittings it requires some amount of force just to move the piston. A shearing action between the V-notch ball and the ball seal figure 1 promotes smooth nonclogging operation.

That is same amount of force is required to pull as well as to push the piston in the cylinder under no load. Foam peanuts also known as foam popcorn snissues packing peanuts or packing noodles are a common loose-fill packaging and cushioning material used to prevent damage to fragile objects during shipping. The unrestricted straight-through flow design provides high capacity for gas steam liquids and fibrous slurries.

Net force required Working load Packing friction. Stuffing Boxes and Seal Chambers are packing and mechanical seal chambers respectively. Generally packing friction is considered to be same for both extension and retraction.

A contoured segmented V-Notch ball. Parker Hannifin Corporation Engineered Polymer Sytems Division Salt Lake City UT Phone. Low-leakage hard seals are found on the piston end of double-acting telescopic cylinders.

The solid packings have much better properties over sponge packing. Design tooling allows for frequent and steady extrusion. An unbalanced seal gives a simpler shaft or sleeve design and will seal up to 147 psi gauge 10 bar and above this balanced seals are requested.

Like all other GKS machines MINI can be equipped with many options. Our marine solid rubber packing is suitable for steel hatch covers used on most new builds. Furthermore we can produce any new designs at.

The basic rotating face mechanical seal design is adaptable to serve a wide range of sealing applications including compressors. For best performance the service. Most texts 1 refer to the seal faces as the primary seal whereas a series of secondary seals are used to seal other areas within the mechanical seal design that would otherwise loose fluid.

Table-tops floor and industrial models Vacuum packaging machines. Check our recipes page to see what more is on the menu. They are shaped to interlock when compressed and free flow when not compressed.

5-13680 Bridgeport Road Richmond BC V6V 1V3 Call us now toll free. The solid packings tend to have longer life span than traditional sponge packing. Email Us email protected Call Us 800 - 837 -.

Packaging can be described as a coordinated system of preparing goods for transport warehousing logistics sale and end usePackaging contains protects preserves. ENVIRO-SEAL Graphite ULF ENVIRO-SEAL graphite ULF packing is designed primarily for environmental applications at elevated temperatures in excess of 232C 450F. Of the high stress design of the packing system.

Henkelman offers the most complete range of professional vacuum packaging machines. Materials often used for standard water duties are carbon for the face and ceramic and if condensate carbon with a nickel-iron. T-Seal Design 3 Seal Type Comparison 4 Materials 5 Materials Ordering Information 6 T-Seal Part Numbers 7 Part Number Cross Reference 8 Design Data Request Form 13 Other Parker Seal Products 15 Offer of Sale BC PPD 3001A Piston and Rod T-Seals.

From the smallest table-top model up to the largest heavy duty double. The selection of secondary seal type often determines the temperature and chemical capabilities of the seal.

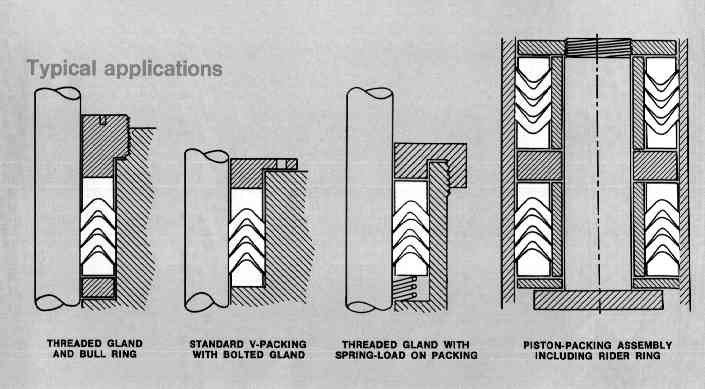

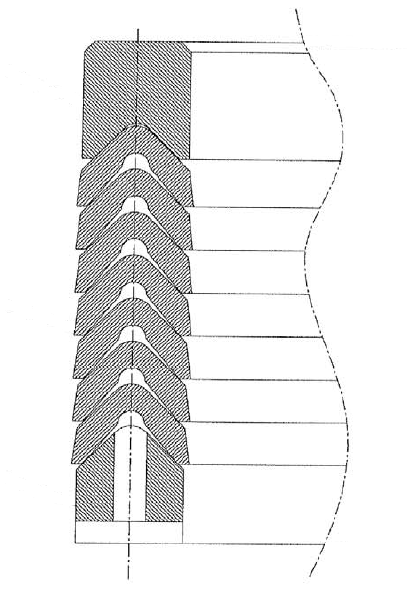

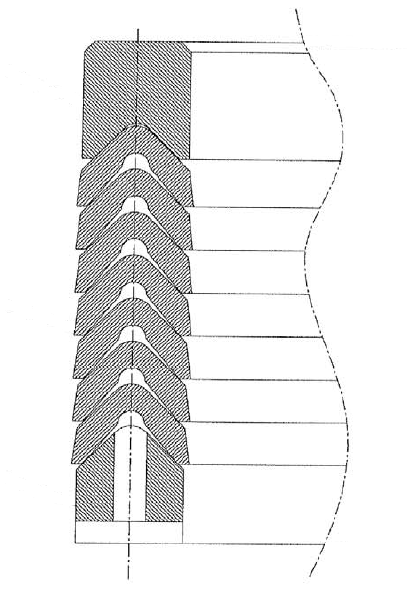

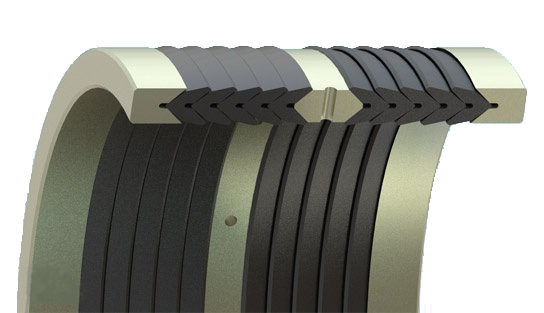

Ptfe V Packings Vee Packing Made Of Ptfe

Nbr Viton V Packing Fabric Seals Manufacturers And Suppliers China Customized Products Price Swks

Vee Packing Seals Ashton Seals

V Packings And Chevron Stacks For Oil Gas Industry Applications Barnwell

Vee Packings For Oilfield Equipment Diyak Ltd Uk

0 comments

Post a Comment